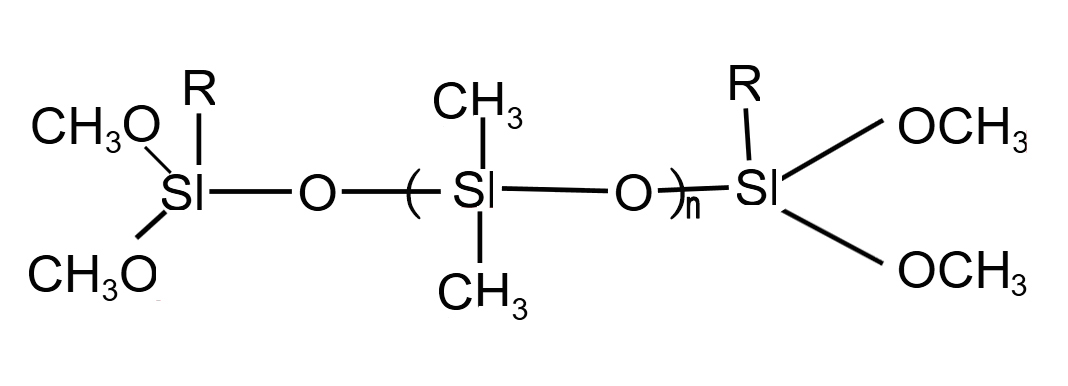

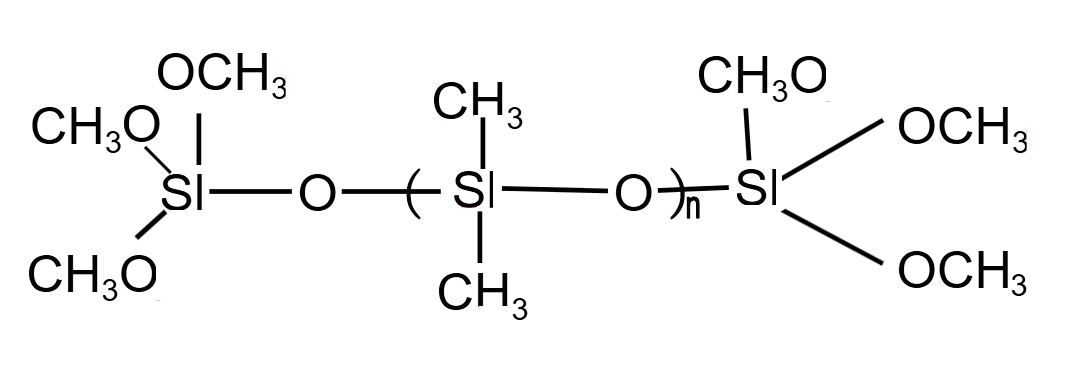

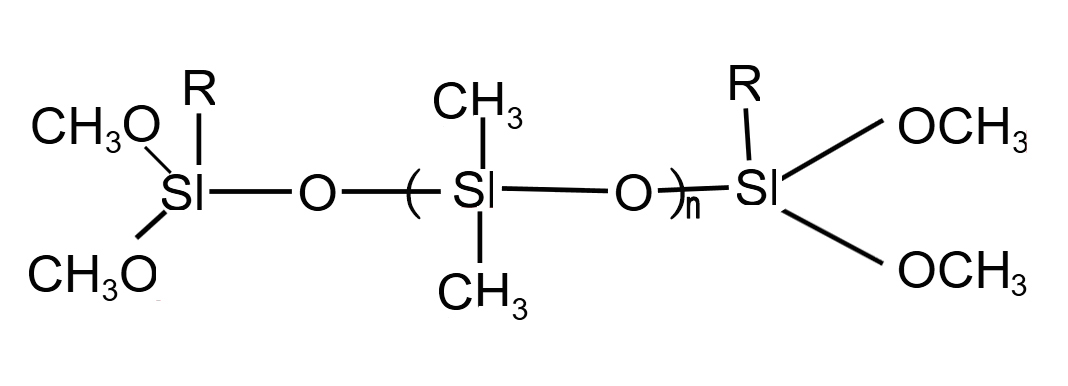

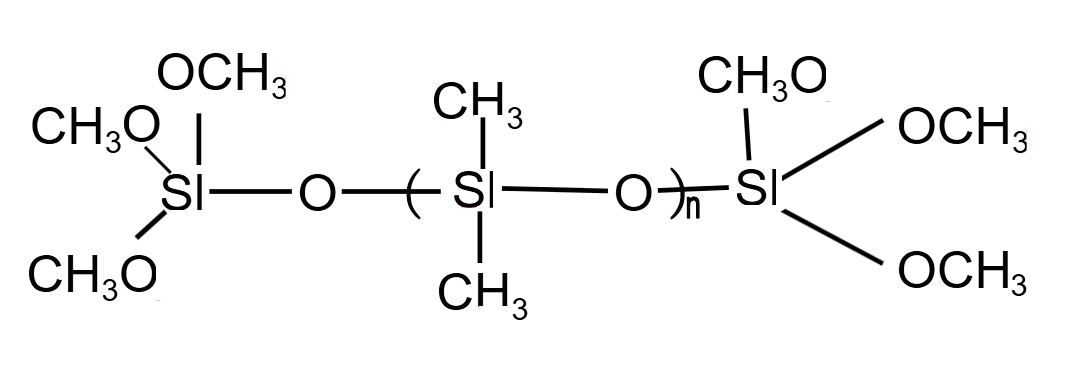

The structure is as follows:

Dimethoxy-terminated PDMS

Trimethoxy-terminated PDMS

It's colorless transparent liquid ,mainly used as a raw material for silicone alcohol-type vulcanized silicone rubber. It’s moisture curing.

Typical Technical Properties:

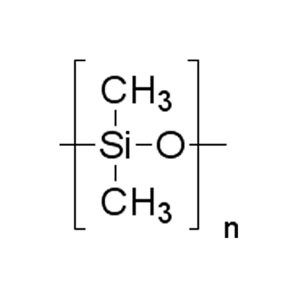

Alkoxy Silicone Fluid LF-TM107 which is known as Alkoxy-terminated 107 rubber is the basic raw material of high-grade dealcoholized RTV silicone rubber ( alcohol-type rubber). Compared with ordinary 107 rubber, it has the following characteristics:

Item | LF-TM107 -600 | LF-TM107 -1000 | LF-TM107 -3000 | LF-TM107 -7000 | LF-TM107 -20000 | LF-TM107 -40000 | LF-TM107 -80000 |

Appearance |

| Light yellow transparent liquid |

|

Viscosity (25°C, mpa.s) | 400-600 | 1000-1500 | 2700-3300 | 6000-9000 | 16000-24000 | 30000-42000 | 70000-90000 |

Alkoxy-terminated 107 adhesive | Regular 107 Adhesive |

No viscosity peak | In 107 adhesive, hydroxyl groups readily undergo condensation reactions with curing agents, such as organic tin and organic titanium, leading to an increase in polymer molar mass and viscosity. |

Excellent storage stability | In the storage process, 107 adhesive reacts with crosslinking agents to generate methanol. Under the catalytic effect, the main chain is prone to degradation into low-molecular-weight siloxanes terminated with single alkoxy groups. As a result, the curing performance of the adhesive rapidly deteriorates, potentially leading to impaired or even inhibited curing. |

Easy to process in production | The hydroxyl groups in 107 adhesive readily form hydrogen bonds with hydroxyl groups on the surface of fillers. The hydrogen bonding interactions make it challenging for the fillers to disperse, resulting in the occurrence of a "structuring" phenomenon and deteriorating processing performance. |

Based on the reasons mentioned above, the overseas production process of alcohol-dehydrogenating type (alcohol-type) RTV-1 silicone rubber often relies on alkoxy-terminated 107 adhesive as the main base polymer. The entire series of alkoxy-terminated 107 adhesive products cover a viscosity range from 200 to 80,000 CPS, with stable product performance and complete end-capping. Supported by a complete set of alcohol-type adhesive technical solutions, the produced alcohol-type adhesives exhibit the following characteristics:

1. Controllable Viscosity and State: The viscosity and state can be controlled, allowing for the production of both high-flow (low viscosity, below 1000 CPS, such as conformal coating/coating adhesive) and thixotropic (paste-like bonding and sealing adhesives, such as solar adhesives, construction glass adhesives).

2. Adjustable Dry Time: The drying time can be adjusted within the range of 3 to 120 minutes;

3. Excellent storage stability with a shelf life of 12 months or more;

4. Low Odor, Low Corrosion, Low Yellowing, Fast Curing;

5. Complete coverage of colors, allowing for the production of both transparent alcohol-type adhesives and mixed-color alcohol-type adhesives;

6. Simplified Production Process, it can eliminate the need for heating and degassing steps, enabling direct material feeding for production.

Applications:

Alkoxy-terminated silicone oil is a versatile organosilicon intermediate with methoxy reactive groups that can undergo condensation reactions with hydroxyl groups, enabling grafting onto organic compounds. It exhibits slow hydrolysis in the presence of water, leading to the formation of a resin with excellent hydrophobic, anti-adhesive, and aging-resistant properties.

Alkoxy-terminated silicone oil finds applications in various fields such as electronic adhesives (bonding, sealing, fixing, thermal conductivity, coating), industrial adhesives (automotive electronics, solar energy, etc.), and construction adhesives (circulating adhesives, mirror adhesives, stainless steel adhesives, structural adhesives, weather-resistant adhesives, etc.).

It can also serve as a cross-linking agent for silicone rubber, replacing conventional ethyl silicate. Silicone rubber cross-linked with alkoxy-terminated silicone oil exhibits superior tensile strength and elongation compared to silicone rubber cross-linked solely with ethyl silicate.

Additionally, alkoxy-terminated silicone oil can be employed as an isolating agent in pressure-sensitive adhesives and as a stabilizer in foam-forming agents. Further hydrolysis can yield effective defoaming agents, release agents, waterproofing agents, anti-stick paper coatings, and water-resistant treatments for powders, including silicone-containing demulsifiers for crude oil dehydration.

Package &Storage:

In 25kg pail, 200kg drum and IBC.

Keep in cool, dry and ventilated place. Keep away from sunlight and fire sources. Keep in unopened containers, shelf life is 12 months from the date of production. It is shipped as non-hazardous substance.

Storage beyond the shelf life does not necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assurance reasons.