Silicone materials have been used in the medical field for more than 70 years. In 1943, Corning and Dow Chemical established the original Dow Corning, a joint venture for the development and production of silicone products, thus opening the era of commercialization of silicone materials. Since then, with its excellent performance, the silicone products of the original Dow Corning have been rapidly applied to various industries. Since the 1950s, its tentacles have extended to the medical field, and the first major silicone medical product, the hydrocephalus shunt, has been launched, demonstrating the potential of silicone in medical applications.

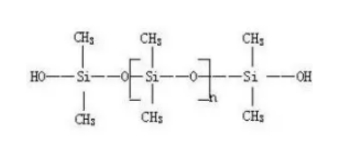

Silicone is a polymer. Unlike the common carbon chain skeleton of polymers, the main skeleton of silicone is an inorganic long chain composed of alternating silicon atoms and oxygen atoms (-Si-O-Si-O-Si-O-). In addition, organic side groups such as methyl, ethyl, and phenyl are also connected to the silicon atom. Therefore, the essence of silicone is a polymer composed of inorganic-organic monomers. Among them, the smallest repeating unit is called siloxane (-O-Si-O-), so silicone is also called polysiloxane.

By regulating the chain length of polysiloxane, the side groups of silicon atoms in the repeating unit, and cross-linking the polymer chain, silicone materials with various properties can be obtained, from liquid to gel, from rubber to hard plastic. According to different molecular structures, these materials can be divided into four categories of products: silicone rubber, silicone oil, silicone resin, and silane coupling agent. The most common polysiloxane material is called polydimethylsiloxane (PDMS, silicone), which is a commonly used additive in chemical products and medicines.

Chemical formula of polydimethylsiloxane

People who are not familiar with silicone can easily confuse these materials based on their "common names". For example, silicone rubber is often referred to as "silicone". The "silicone" used for breast augmentation is actually a silicone rubber shell filled with liquid polysiloxane. In chemical laboratories, there is also a common reagent called silica gel. This is a non-crystalline silicon dioxide with an open porous structure and strong adsorption. It can adsorb a variety of substances and is often used to prepare chromatography columns. (What is silicon dioxide? The main component of sand is silicon dioxide.)

Silicone rubber and silica gel are not the same material

Silicone rubber is widely used as a medical raw material mainly based on its good biocompatibility and plasticity. Siloxane, the main component of silicone rubber, is an inert molecule with good chemical and thermal stability, durability, hydrophobicity, and low surface tension. Long-term experiments have shown that silicone rubber has low cytotoxicity and good blood compatibility. In addition, silicone rubber is usually cross-linked by liquid polysiloxane, which allows silicone rubber products to be designed in various shapes according to the needs of the application scenario. The application of silicone rubber in medical devices includes but is not limited to various molds, prostheses, heart valves, blood oxygenators, renal dialysis components, intravenous drug and blood transfusion systems, respirators, ventilation masks, breathing tubes, catheters,

etc.

![]()

Various medical silicone rubber products

Of course, silicone rubber is not without its shortcomings. Due to the hydrophobic properties of the material itself, silicone rubber has a large friction resistance when in contact with human tissue. Therefore, silicone catheters need to be additionally lubricated or a layer of hydrophilic lubricating coating is prepared on the surface of the catheter during use. In ophthalmic applications, the surface of silicone-based contact lenses needs to be hydrophilized to avoid dry eyes and discomfort. In addition, silicone products still face the risk of thrombosis when in long-term contact with blood. The surface of new silicone products will improve the blood compatibility of the product by preparing an anticoagulant coating.